The earliest applications return to 6000 BC or earlier with the production of brewage bread baking and cheese and wine creating whereas the primary purposeful microbe oxidisation dates from 2000 BC with vinegar production. The Food and Drug Administration.

Manufacturing Process Liquid Products Nikken Foods

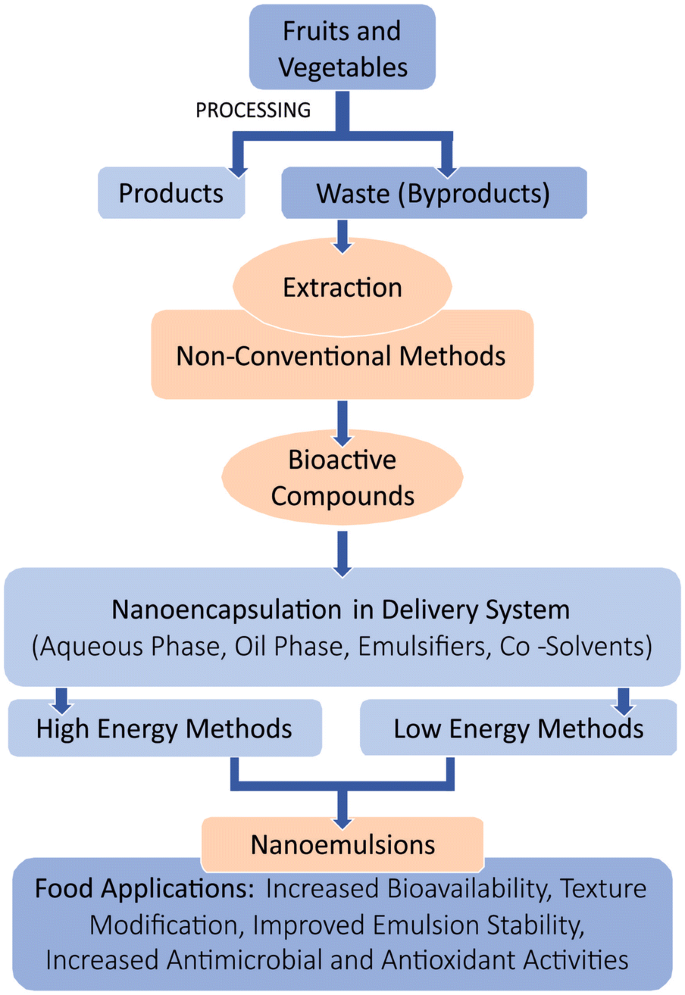

Valorization Of Fruits And Vegetables Waste Through Green Extraction Of Bioactive Compounds And Their Nanoemulsions Based Delivery System Bioresources And Bioprocessing Full Text

Food Processing Operations 1 In The Food Industry

The cannabis-oriented health and wellness company noted that by leveraging this patent it aims to pursue licensing opportunities for its unique extraction process with manufacturers.

Extraction process in food industry. While innovation is one of the most exciting aspects of the cultivation industry. However a typical supercritical CO2 machine costs way too much for most people to own and use one of their own at home. The flesh products used in pet foods must first be rendered or processed to separate the water fat and protein components including soft offals viscera and hard offals eg.

Many studies have shown that supercritical CO 2 is very effective in the removal of oil but phospholipid classification is still in the research stage mainly because phospholipids are not soluble in supercritical CO 2. They are also widely used for various industries such as textile paper detergent and food industry. The system could then be used by the food industry to isolate or eliminate particular flavors.

Primary purposes of edible food packaging. Fermentation organic chemical synthesis and biological and natural extraction Theodore and McGuinn 1992. Enzymes Used In The Food Industry.

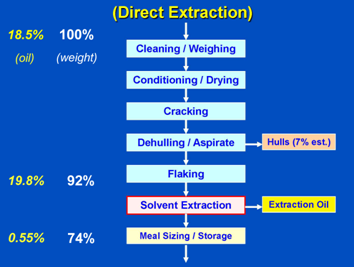

It is often necessary to dry the samples prior to oil extraction using solvents because many organic solvents are immiscible with water and cannot easily penetrate foods containing much water and therefore extraction would be inefficient Chemat et al 2015 Señoráns and Luna. In addition it is cost-effective as consumption of solvent is reduced and is effective in removal of anti-nutritional factors toxins and avoid degumming process 23 25. A supercritical closed loop industrial CO2 extraction machine is used to extract different molecules from botanicals using liquid or supercritical CO2.

Moreover this process is environmental-friendly safer healthier simultaneous oil and protein extraction can be done without compromising the quality. Hot extraction process is a process in which heat is used to break the emulsion between water and oil molecules. Except for the ingredients the general manufacturing process for pet food is similar to that for processed food.

It began with our vision to promote safer healthier extraction systems and extracted products for human consumption across industries. CO2 extraction is the cutting edge of the cannabis industry. Distillation process involving the conversion of a liquid into vapour that is subsequently condensed back to liquid form.

At Cedarstone Industry we work in tandem with our clients to arrive at truly turn-key solutions for commercial food. Food process through the employment of biological agents is traditionally a well-established approach. Olive oil extraction is the process of separating the oil from the other fruit contents vegetative extract liquid and solid material.

This process is only needed when the oil was extracted at high pressurehigh temperature supercritical because this intense extraction pulls everything from the plant including material you dont want in the final products. The Australian red meat and livestock industry is committed to food safety integrity and traceability. The use of CO2 means that typical solvents that might not only be dangerous to work with but also could affect the chemical composition of the oils you are extracting are no longer a concern creating a high-performance extraction system for.

There are several steps involved in the preparation of a food sample for solvent extraction. In juice industry cellulases are applied in combination with other macerating enzymes for increasing process performance and yield improving the extraction methods clarification and stabilization of juices. Leading Stainless Steel Process Equipment Manufacturer.

Solutions to process powders solids and liquids to deliver high throughput reliability and final product consistency. Basic production of bulk drug substances may employ three major types of processes. Pioneering Supercritical CO2 Systems.

Olive oil extraction is the process of extracting the oil present in olive drupes known as olive oilOlive oil is produced in the mesocarp cells and stored in a particular type of vacuole called a lipo vacuole ie every cell contains a tiny olive oil droplet. Costa B et al Materials. It is exemplified at its simplest when steam from a kettle becomes deposited as drops of distilled water on a cold surfaceDistillation is used to separate liquids from nonvolatile solids as in the separation of alcoholic liquors from fermented materials or in the.

Caffeine extraction used to be done using liquidliquid extraction specifically direct and indirect liquidliquid extraction Swiss Water Method but has since moved towards super-critical CO 2 as it is cheaper and can be done on a commercial scale. This vision has led more than one industry to embrace ethanol and CO2 extraction as non-toxic. Winterization is the process to remove undesirable elements that were extracted from the plant for example fats waxes and lipids.

Chitosan as a Valuable Biomolecule from Seafood Industry Waste in the Design of Green Food Packaging. Processed Food PDF 31MB This industry capability statement provides an overview of Australian capability in processed food manufacturing including examples of some of the many Australian companies with specialist expertise. As the emulsion is being stabilized by proteins the heating process aims to.

Biomolecules and Materials from Agro-Industrial Wastes. Costa B and Andrade C. Figure 792 Manufacturing process in the pharmaceutical industry.

Neptune is a health and wellness products company with more than 50 years of combined experience in extraction purification and formulation of value. While heating ethanol can increase the extraction processs efficiency ethanol is a good solvent for extracting terpenes and cannabinoids. We use a completely custom physical refining process in our cutting-edge State of Tennessee approved food processing facility for specialty oils to produce the purest and highest quality finished product in the industry.

Material Handling Systems From receiving-feeding storage-discharge and conveying to vision based robots and primary secondary and tertiary packaging. Supercritical CO 2 is the most commonly used extraction solvent in the fine chemical industry especially in the extraction of fragrance food additives and surfactants. You can still make high quality completely non-toxic CO2-extracted cannabis concentrates at home with some simple materials some easily obtainable dry ice and some good organic weed.

VAPG Program Opportunities for Value-added Agriculture Business and Economic Concepts and Principles Barriers to Entry and Exit Breakeven Selling Price Product Life Cycle Economies of Scale and Scope Business Expansion Business Management Business Workbench Risk Management for Specialty Crops Food Industry Food Supply Chain Analysis Practitioner and Education Resource Database. Eden Labs has been engineering Supercritical Fluid Extraction SFE- CO2 since 1995 and Ethanol distillers since 1994. Our differentiated extraction process was developed through years of science-backed research and represents the continued progress of our IP.

What Is Extraction The Theory And How It S Applied To Food Food Crumbles

Review Of Green Food Processing Techniques Preservation Transformation And Extraction Sciencedirect

Solvent Extraction

Olive Production Oil Plants Extraction Technology Farm Tanks Press Fruits Manufacturing Bottle Crushed Food Vector Stock Vector Illustration Of Background Object 132707757

A Review Of Sustainable And Intensified Techniques For Extraction Of Food And Natural Products Green Chemistry Rsc Publishing Doi 10 1039 C9gc03878g

A Critical Analysis Of Extraction Techniques Used For Botanicals Trends Priorities Industrial Uses And Optimization Strategies Sciencedirect

Liquid Liquid Extraction Wikipedia

Faq About Pulsed Electric Field Processing